Cereal Boxes: Custom Packaging Solutions for Modern Breakfast Brands

Introduction: Why Cereal Packaging Matters in Competitive Markets

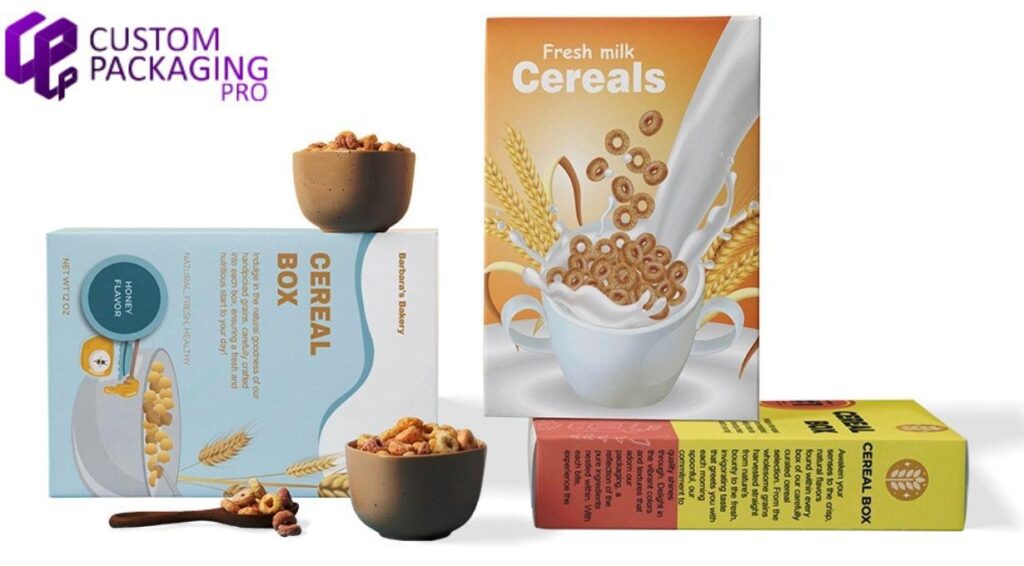

In the United States breakfast food industry, cereal boxes do far more than hold a product. They represent brand identity, communicate nutritional value, ensure product protection, and influence purchasing decisions within seconds. Grocery aisles are crowded with cereal brands competing for attention, from family-size corn flakes to mini cereal boxes in variety packs. In this competitive environment, professionally designed cereal packaging becomes a critical business asset.

For manufacturers, private labels, and emerging food startups, cereal boxes play a direct role in shelf impact, logistics efficiency, regulatory compliance, and customer trust. Thoughtful cereal packaging supports brand growth, improves storage and shipping, and strengthens retail performance across physical stores and eCommerce platforms.

Custom Packaging Pro works with breakfast brands across the USA to develop cereal boxes that balance branding, protection, sustainability, and scalability.

What Are Cereal Boxes and Why They Matter

Cereal boxes are rigid folding cartons, most commonly made from cardboard or paperboard, designed to protect breakfast cereal products while presenting them in a retail-ready format. Inside the box, a sealed plastic or recyclable bag maintains freshness, while the outer box delivers structure, stackability, and branding space.

Cereal packaging matters because it directly affects:

• Product freshness and shelf life

• Brand visibility and recognition

• Consumer perception of quality

• Compliance with labeling and food safety standards

• Shipping, storage, and warehouse efficiency

Examples include big cereal boxes for family packs, small cereal boxes for single servings, mini cereal boxes bulk packs for hotels and schools, and creative boxes used for promotional cereals like fruit loops cereal or fruity pebbles cereal box editions.

Whether selling classic cereal brands, launching a new organic line, or offering variety pack cereal assortments, packaging becomes the physical bridge between the product and the customer.

Key Benefits of Custom Cereal Packaging

Custom cereal boxes allow brands to move beyond generic cartons and build packaging aligned with business goals.

Key benefits include:

• Stronger shelf presence through branded cereal boxes

• Accurate sizing for portion control and logistics

• Improved stacking, storage, and shipping performance

• Design flexibility for marketing campaigns and limited editions

• Support for regulatory labeling and nutrition panels

• Options for eco-friendly materials and coatings

• Consistency across retail, wholesale, and eCommerce channels

Custom cereal packaging also allows brands to design around specific product needs, whether cereal boxes mini for sampling programs or big cereal boxes for warehouse retailers.

Common Box Types and Use Cases

Cereal packaging is not limited to one structure. Different business models require different carton styles.

Straight tuck-end cereal boxes

The most common cereal box type. Used for standard retail packaging across major cereal brands.

Reverse tuck-end boxes

Ideal for automated filling lines and high-volume production.

Auto-lock bottom boxes

Used for heavier cereals, granola blends, or multi-bag packaging.

Window cereal boxes

Allow partial product visibility for premium or organic cereals.

Mini cereal boxes

Popular for variety pack cereal assortments, hotels, airlines, school programs, and promotional kits.

Display-ready cereal boxes

Designed to convert from shipping cartons into shelf displays.

These structures support a wide range of business needs, from cereal boxes storage solutions in warehouses to cereal boxes asda-style retail packaging commonly seen in large grocery chains.

Standard Sizes vs Custom Sizing

Cereal boxes come in many standard dimensions, but custom sizing allows brands to optimize material usage, shipping costs, and shelf fit.

Common cereal box size ranges include:

| Box Type | Typical Dimensions (L x W x H) | Use Case |

| Mini cereal boxes | 2 x 1.5 x 4 inches | Sampling, hotels, kids packs |

| Small cereal boxes | 5 x 2 x 8 inches | Single-serve retail |

| Standard cereal boxes | 7 x 2.5 x 11 inches | Grocery store shelves |

| Big cereal boxes | 9 x 3 x 14 inches | Family packs, warehouse clubs |

Custom sizing supports products like cereal boxes cardboard cartons for specialty grains or promotional cereal box book report projects often used in educational programs.

Technical Note on Length, Width, and Height

Understanding cereal box dimensions is essential for packaging efficiency.

• Length refers to the front panel width.

• Width is the side depth of the box.

• Height is the vertical measurement from base to top.

These dimensions determine surface area, shelf footprint, and shipping carton layout. Brands calculating how to find surface area of a cereal box often do so to estimate printing coverage, label space, and material costs.

Precise length, width, and height measurements also help answer operational questions such as how many ounces are in a cereal box, how many cups in a box of cereal, and how much cereal is in a box based on volume and density.

Materials Used in Cereal Packaging

Cereal boxes must balance food safety, strength, print quality, and sustainability.

| Material | Strength | Print Quality | Sustainability | Typical Use |

| SBS paperboard | High | Excellent | Moderate | Premium cereal boxes |

| Kraft paperboard | Medium | Good | High | Organic and eco brands |

| Recycled cardboard | Medium | Good | Very high | Sustainable cereal packaging |

| Plastic inner bags | Flexible | Not printed | Varies | Moisture barrier |

| Compostable liners | Medium | Not printed | Very high | Eco-friendly solutions |

Cereal boxes plastic components are usually limited to inner liners, while the outer cereal boxes cardboard structure provides branding and stacking stability.

Printing and Branding Options

Cereal boxes offer large printable surfaces, making them powerful marketing tools.

Popular printing options include:

• Offset printing for large production runs

• Digital printing for short runs and seasonal designs

• Flexographic printing for cost-efficient bulk packaging

Branding elements often include:

• High-resolution product imagery

• Nutrition panels and ingredient lists

• Mascots and illustrations such as cereal with a frog on the box

• Interactive elements like a cereal box maze or QR codes

• Educational or promotional panels on the side of the cereal box

These features help brands connect emotionally with buyers while delivering essential product information.

Extra Functional and Premium Features

Modern cereal packaging goes beyond simple cartons.

• Moisture-resistant coatings

• Resealable inner bags

• Window cutouts

• Tamper-evident seals

• Matte, gloss, or soft-touch finishes

• Embossing and spot UV highlights

• Stack-optimized structural reinforcements

Premium cereal boxes often use these enhancements to support upscale positioning and longer shelf life.

Eco-Friendly Packaging Solutions

Sustainability is now a central factor in cereal packaging decisions.

Eco-friendly cereal boxes may include:

• FSC-certified paperboard

• High recycled content cartons

• Compostable or recyclable inner liners

• Soy-based inks

• Reduced-material structural designs

Brands also use on-pack messaging to educate consumers through recycling tips for cereal boxes and bags, encouraging responsible disposal and reinforcing brand credibility.

Wholesale and Bulk Packaging Benefits

Wholesale cereal packaging requires consistency, cost control, and logistics efficiency.

Benefits include:

• Lower per-unit costs

• Optimized pallet stacking

• Reliable structural performance

• Standardized sizing for automated systems

• Easier sourcing of mini cereal boxes bulk quantities

Wholesale cereal boxes are commonly used by large cereal brands, private labels, schools, hospitality providers, and subscription box services.

Retail, eCommerce, and Business Use Cases

Cereal packaging must perform across multiple distribution channels.

Retail: Shelf presence, barcode placement, durability, and tamper resistance.

eCommerce: Compression strength, shipping protection, and damage reduction.

Food service: Mini cereal boxes, portion packs, and bulk cartons.

Corporate and education: Promotional cereal boxes, branded kits, and cereal box storage solutions.

Each channel requires tailored cereal packaging strategies to maintain product quality and brand integrity.

USA Packaging Market Trends

The US cereal packaging market continues to evolve alongside consumer expectations and retail shifts. Key trends include:

• Growth in mini cereal boxes and variety pack cereal formats

• Increased demand for recyclable and compostable materials

• Greater emphasis on storytelling and brand transparency

• Rise of direct-to-consumer cereal brands

• Integration of smart packaging and QR engagement

• Custom sizing to reduce freight and warehousing costs

Cereal brands are using packaging as both a marketing platform and an operational optimization tool.

Why Choose Custom Packaging Pro

Custom Packaging Pro supports cereal brands across the USA with packaging solutions designed around real business needs. The focus is on material performance, accurate sizing, reliable printing, and scalable production.

From small cereal boxes for startups to high-volume cereal packaging programs, the approach emphasizes structural precision, branding consistency, and sustainable options. Rather than one-size-fits-all cartons, Custom Packaging Pro develops cereal boxes aligned with product goals, compliance standards, and long-term growth strategies.

Final Thoughts

Cereal boxes are not simply containers. They are communication tools, logistical assets, and brand ambassadors. In a crowded breakfast aisle, the right cereal packaging supports product protection, builds recognition, and enhances consumer trust.

By investing in well-structured, professionally branded, and responsibly sourced cereal boxes, cereal brands position themselves for stronger retail performance, smoother operations, and long-term market relevance.

Frequently Asked Questions

1. What material is best for cereal boxes?

Most cereal boxes use paperboard or cardboard for strength and print quality, combined with an inner liner for freshness. Recycled and FSC-certified boards are increasingly popular.

2. What are standard cereal box dimensions?

Standard cereal boxes often measure around 7 x 2.5 x 11 inches, but mini cereal boxes and big cereal boxes vary widely based on product size and market needs.

3. How many ounces are in a cereal box?

The number of ounces in a cereal box depends on box dimensions, cereal density, and brand portioning. Typical boxes range from 8 to 24 ounces.

4. Can cereal boxes be customized for branding?

Yes. Branded cereal boxes can include custom sizing, full-color printing, special finishes, and functional enhancements.

5. Are cereal boxes recyclable?

Most cardboard cereal boxes are recyclable. Many brands also provide recycling tips for cereal boxes and bags to support consumer education.

6. Can custom cereal packaging support wholesale and eCommerce?

Custom cereal boxes can be engineered for both retail shelves and shipping durability, making them suitable for wholesale distribution and direct-to-consumer fulfillment.